The manufacturing of solar panels is costly primarily due to the high-quality materials and processes required. High-purity silicon, the backbone of most solar cells, requires intensive processing which is both energy-consuming and costly. Furthermore, the advanced manufacturing technologies needed to transform raw materials into efficient and durable solar panels add significant overheads. These processes are not only capital intensive but also require high operational expenses including skilled labor, research and development, and adherence to stringent environmental standards.

1. High-Quality Materials

Solar panels are mostly made of silicon, which has to be processed into high-purity polysilicon for photovoltaic cells. This process is highly energy-intensive, using a lot of electricity to purify and refine silicon from its natural state.

The purity of polysilicon is important because even small impurities can really reduce the efficiency of solar cells. Achieving this level of purity requires fancy equipment and strict quality control, which significantly increases production costs.

Additionally, the demand for high-purity silicon can make prices go up and down, which affects the overall expense of solar panel manufacturing.

2. Advanced Manufacturing Processes

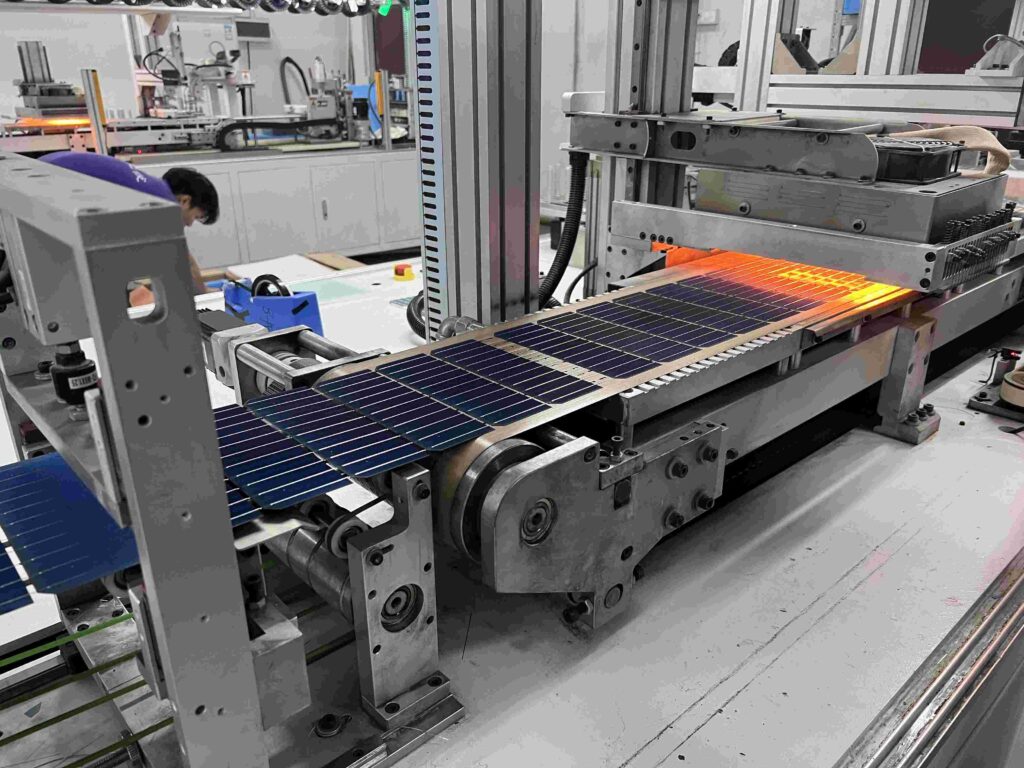

The transformation of polysilicon into wafers, cells, and ultimately solar panels requires complex and expensive machinery. This process demands precise control over temperature and environmental conditions to ensure material integrity and optimal efficiency. The machinery used is not only costly but also needs frequent updates to incorporate the latest technological advancements.

Additionally, the fabrication process involves multiple meticulous stages, each requiring specialized equipment for tasks such as cutting, coating, and assembling, which further escalates the overall manufacturing costs.

3. Research and Development (R&D)

Investing in research and development (R&D) is critical for advancing solar technology, aiming to boost efficiency and drive down costs. However, R&D is inherently expensive due to the need for extensive testing, prototyping, and validation processes. These steps ensure that new innovations are practical and reliable enough for mass production.

Additionally, R&D teams must constantly explore new materials and techniques, requiring significant investment in both human expertise and advanced equipment. This continuous cycle of innovation is essential to stay competitive in the rapidly evolving solar industry but adds a substantial cost burden to manufacturers.

4. Labor Costs

Despite increased automation in solar panel manufacturing, the requirement for skilled labor remains high. Professionals in this field are needed for the design, monitoring, and maintenance of the production processes. These roles demand a high level of expertise and technical knowledge, contributing to significant labor costs, particularly in regions with higher wage standards.

Moreover, ongoing training and development are essential to keep staff updated with the latest technological advances, adding to the overall employment expenses. The specialized nature of these jobs means that cutting labor costs without affecting product quality can be challenging, impacting the overall cost structure of solar panel manufacturing.

5. Environmental and Safety Regulations

Solar panel manufacturers are required to adhere to stringent environmental and safety regulations, which vary widely between countries. Compliance with these regulations necessitates the implementation of additional manufacturing processes and the acquisition of specialized equipment, both of which increase production costs.

These standards ensure the safe handling of materials and the disposal of industrial waste, protecting both the environment and worker safety.

Moreover, meeting these requirements often involves regular audits and modifications to factory operations, further inflating operational expenses and impacting the overall cost structure of producing solar panels.

6. Energy Consumption

The production of solar panels is highly energy-intensive, especially during the refinement of silicon and the manufacturing of photovoltaic cells. This significant energy consumption not only adds to the production costs but also affects the environmental footprint of the industry.

High energy use is required to maintain the precise conditions needed for the manufacture of high-quality solar panels. This includes sustaining high temperatures for silicon melting and maintaining clean room standards for assembling photovoltaic cells. As energy costs vary globally, this factor can significantly influence the overall cost effectiveness and sustainability of solar panel manufacturing.

7. Economy of Scale

While economies of scale have helped reduce the cost of solar panels over time, the initial setup costs for manufacturing facilities remain prohibitively high. These start-up expenses include the cost of acquiring advanced manufacturing equipment and building adequate facilities to house production lines.

This high capital expenditure poses a significant barrier to entry for new companies and represents a substantial ongoing investment for existing manufacturers. Achieving economies of scale is crucial for reducing per-unit costs, but reaching the necessary production volume to benefit from these reductions requires substantial initial and sustained financial investment.

8. Warranty and Longevity

Solar panels are generally sold with a long-term warranty of 20 to 25 years, underscoring the need for high durability and minimal performance degradation over time. To meet these standards, manufacturers must use durable materials and implement robust manufacturing processes.

These requirements significantly increase production costs, as higher quality materials and more stringent quality control processes are needed to ensure panels can withstand environmental factors such as UV exposure, temperature fluctuations, and inclement weather.

Consequently, the commitment to long-term quality assurance adds a considerable expense but is crucial for maintaining consumer trust and product reliability.

Conclusion

The manufacturing of solar panels involves expensive materials and sophisticated technology. While costs have been decreasing due to technological advancements and increased production scales, significant challenges remain.

Efforts to reduce the cost of solar panels are ongoing, focusing on improving material efficiency and manufacturing processes to make solar energy more accessible worldwide. These efforts not only aim at cost reduction but also at improving the sustainability of solar energy production to benefit the global economy and environment.